OEM-spuitpomp wordt meestal aangepast met 50ml of 100ml in vloeibare behandeling met hogere capaciteit van OEM-systemen. Hoge nauwkeurigheid en hoge herhaalbaarheid maken ditElektrische spuit pompZeer populair voor constant specifiek volume het verstrekken systeem, maakt het programmeerbare controlesysteem het ook flexibeler in verschillende toepassingen en gebieden.

Volume | 50ml, 100ml | |

Accuracy | ≤1% @100% stroke | |

Repeat accuracy | 0.3%– 0.7% @100% stroke | |

Pressure | 0-1.0Mpa (air) | 0-1.2Mpa (water) |

Service life | 3 million times no leakage (media: water) | |

Detection | Photosensor check original piston position for accurate location | |

Actuator | Ball screw (Lead 2mm) | |

Fluid path | Borosilicate cylinder, PTFE piston, PTFE outlet | |

Max pressure | Positive air pressure 0-1.0Mpa / Negative air pressure 0-0.05Mpa | |

Connection | 1/4-28UNF | |

Communication | RS232/RS485/CAN | |

Baud rate | RS232/RS485: 9600dps, 19200dps, 38400dps, 57600dps, 115200dps CAN: 100Kbps, 200Kbps, 500Kbps, 1Mbps | |

Device add. & Parameter setting | Serial Pont | |

Dimension (L*W*H) | Different model different dimension | |

Power supply | DC24V/1.5A | |

| Max Power | 15W | |

Working temperature | 5 – 55℃ | |

Working humidity | < 80% relative humidity, non-condensing | |

Delivery time | About 20-25working days | |

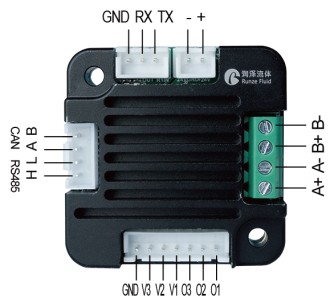

Port | Description | Port | Description |

H | CANH | B+/B- | Phase B wiring |

L | CANL | A+/A- | Phase A wiring |

A | RS485 A | O1 | Optocoupler wiring |

B | RS485 B | O2 | |

GND | GND | O3 | |

RX | RS232 RX | V1 | |

TX | RS232 TX | V2 | |

- | DC24V positive | V3 | |

+ | DC24V negative | GND |

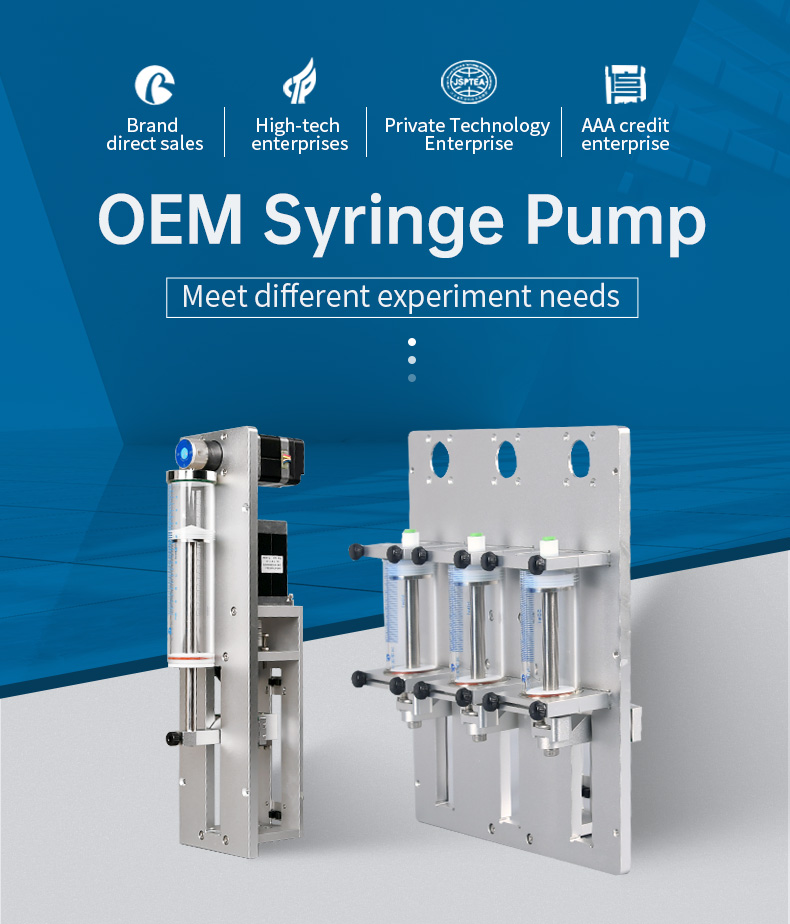

Nanjing Runze Fluid Control Equipment Co., Ltd. supports customization in research and development, engineering, design and manufacturing injection molds and in precise injection-molding for the medical, industrial, laboratory, environmental, electronic and consumer products. The quality of molding decided the quality of final products, we have introduced precision molds processing center to produce high-quality parts according to R&D designs.

RUNZE have established business system from R&D, production, marketing to after-sale service, product line from high precision syringe pump, multiport valve, high pressure solenoid valve, gastight syringe, peristaltic pump, plastic fittings, tubing to OEM parts. Our 3000 cubic meters manufacturing base was set up with different kinds of injection molding machine, EDM center,

components machining center, grinding machine for fluid parts processing. As a design and manufacturing company, we have enough capabilities to provide our customers with components or system. OEM services as well as technical support. As a Hi-tech qualified enterprise, we have acquired certificates of ISO9001, design and utility patents, CE, RoHs, we will further apply for more new design patents, CE, RoHs, Reach certificates for our product.

We keep upgrading the production and detection equipment to bring our customers with high quality products but much competitive and stable prices.

1. Size, normally 500ml big volume syringe; Custom injectors 50ML\100ML syringe. High borosilicate glass body, 304 stainless steel push rod, Polytetrafluoro piston. High precision, corrosion resistant, maximum pressure 0.68Mpa. Standard 1/4-28UNF thread, tight and well sealed.

2. Material: SST, POM ,PEEK.

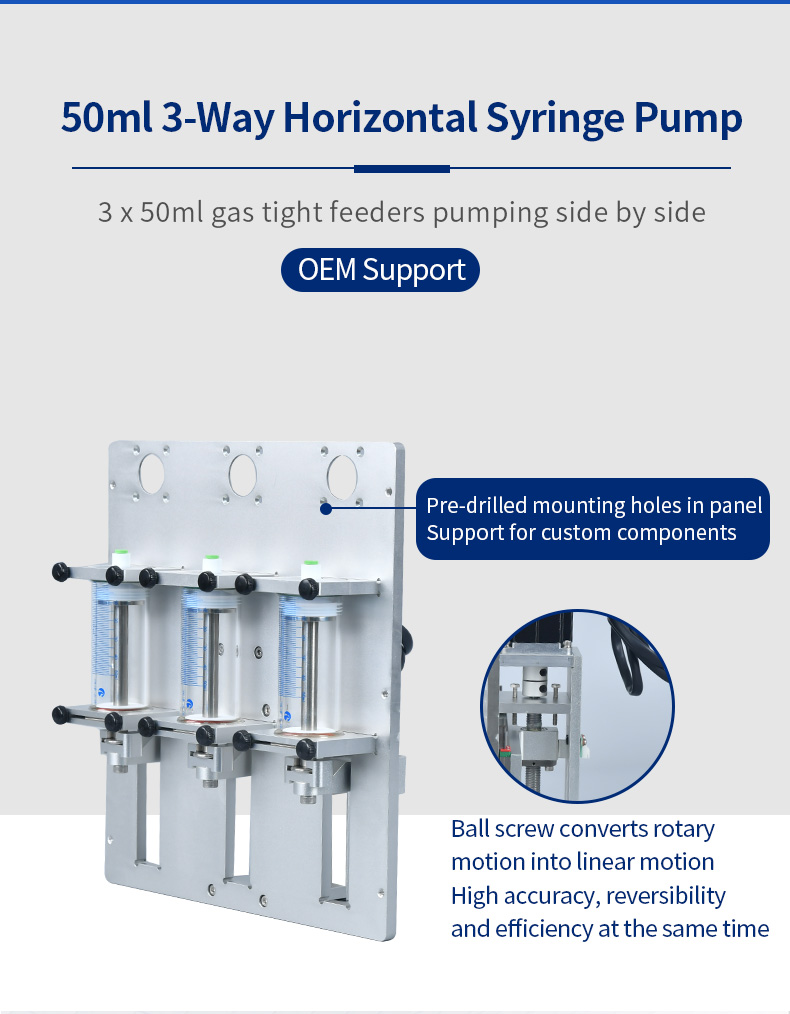

3. Mounting size: can customized mounting hole according customer need. Pre-drilled mounting holes in panel. Support for custom components

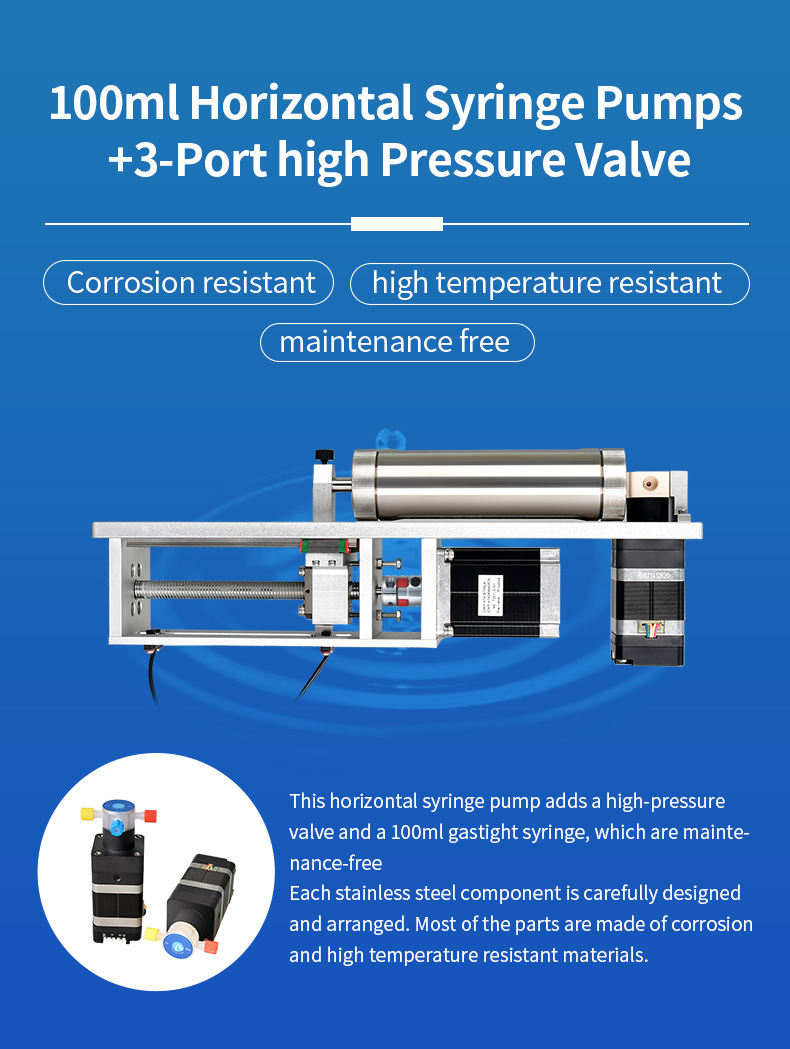

1. 100ml Horizontal syringe pumps +3-port high pressure valve

Corrosion resistant, high temperature resistant, maintenance free

This horizontal syringe pump adds a high-pressure valve and a 100ml gastight syringe, which are maintenance-free

Each stainless steel component is carefully designed and arranged. Most of the parts are made of corrosion and high temperature resistant materials.

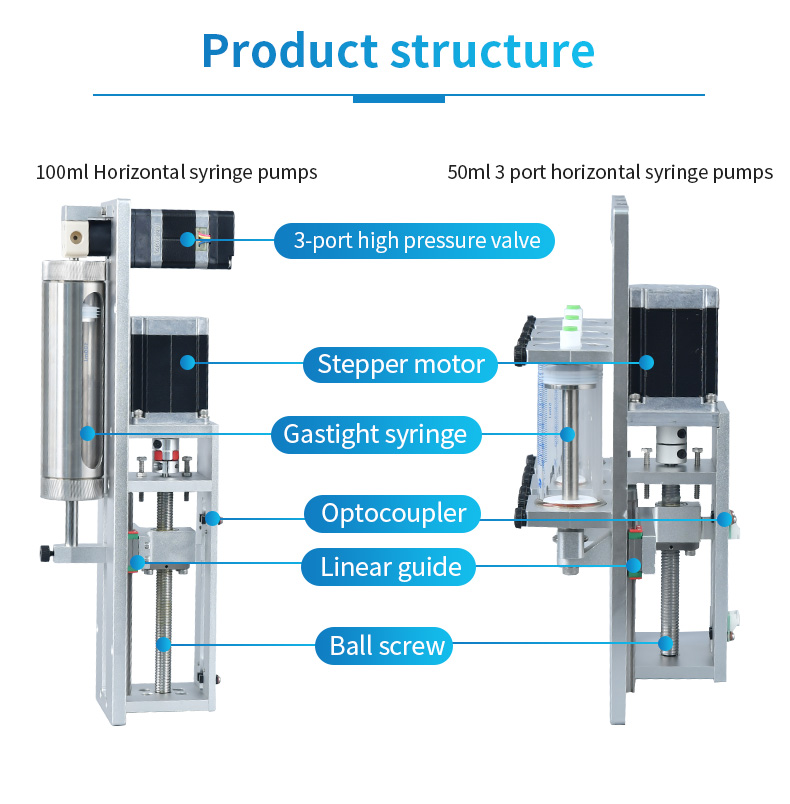

2. 100ml Horizontal syringe pumps / 50ml 3 port horizontal syringe pumps

3-port high pressure valve

Stepper motor

Gastight syringe

Optocoupler

Linear guide

Ball screw

3. 50ml 3-way horizontal syringe pump

3 x 50ml gas tight feeders pumping side by side

OEM support

Pre-drilled mounting holes in panel

Support for custom components

Ball screw converts rotary motion into linear motion

High accuracy, reversibility and efficiency at the same time